Basic Info

| Model NO. | white Plexiglass Pipe Tube Clear Extruded Acrylic |

| Application | Decoration and Lighting |

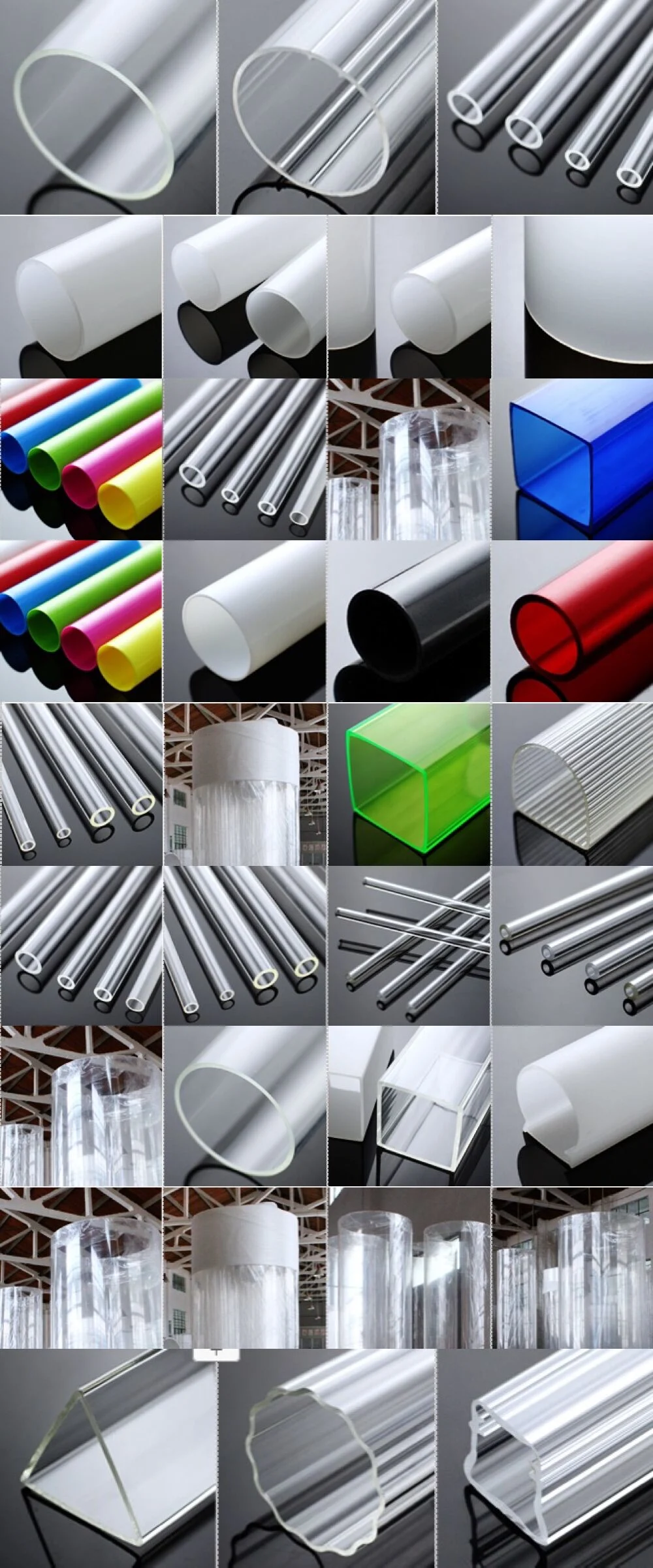

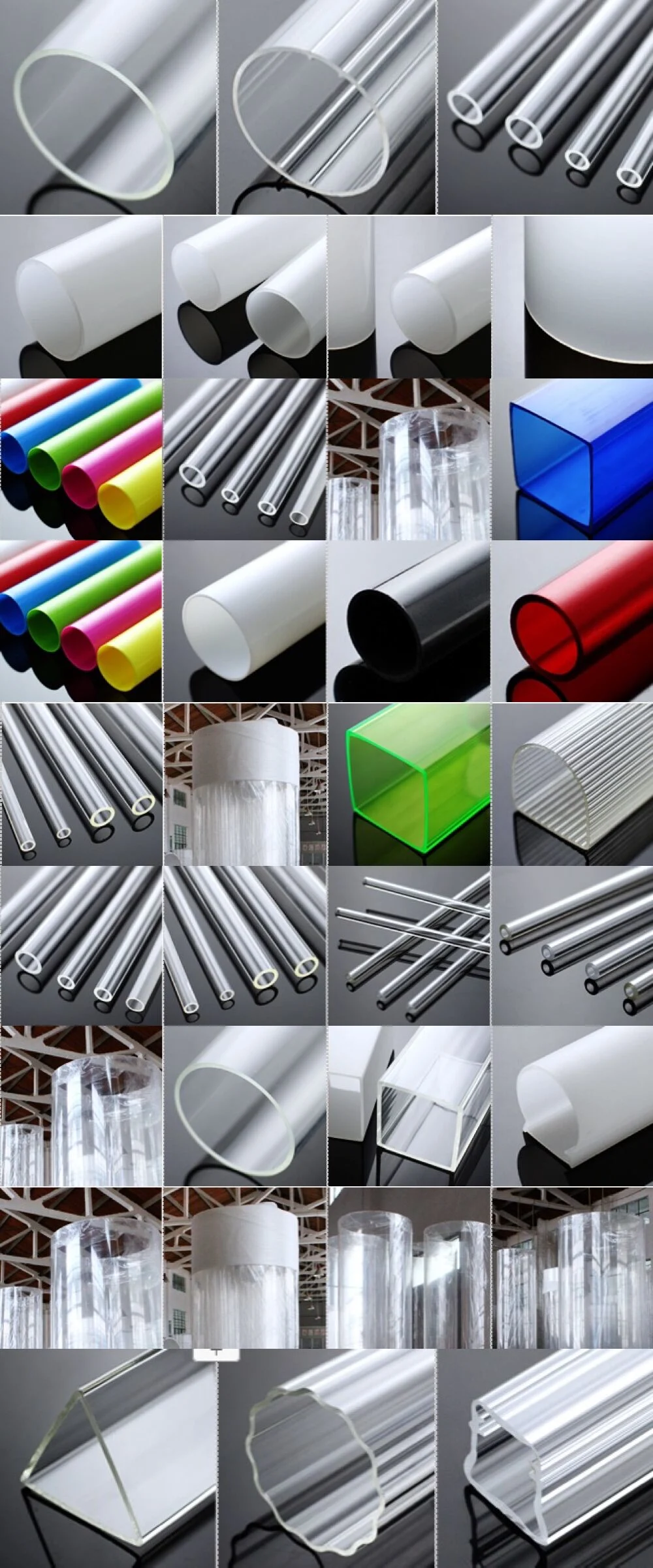

| Shape | Round, Square, Triangle, Irregular |

| Process | Extruded or Cast |

| Thickness | 0.3-20mm |

| Packing | Carton + Pallet |

| Length | 1meter 2meter, Unlimited |

| Name | Acrylic Plastic Tube Acrylic Pipe |

| Lead Time | 5-25 Days |

| Payment | T/T |

| Service | Can Make as Your Drawing |

| Port of Loading | Huangpu |

| Sample | Free of Charge |

| Factory | Yes |

| Transport Package | Pallet and Carton |

| Specification | diameter 1.5mm-1000mm |

| Trademark | ALANDS |

| Origin | China |

| HS Code | 391729000 |

| Production Capacity | 7000 Tons |

Product Description

ALANDS specialized in extrusion production of acrylic (pmma) tube with 10 years manufacturing experience. We produce outer diameters from 5mm-250mm regular size tube, 1.5mm-4mm ultra-thin tube, and more than 300mm oversized tube.

According to different clients' requestments, tube's size, thickness, length, color all can be changed. We have rich inventories, large or small quantities are both available.

Acrylic (pmma) tube has good advantages of high transparency, high hardness, corrosion resistance, UV resistance, surface smoothness. Generally used for lighting, crafts, house deco, medical equipment, building, algae bioengineering, and the other different functions. |

| OUR ADVANTAGES | | Factory covers 20,000 square meters | 10 extrusion production lines | | Product sructure design capability | CAD/CAM | | Provide sample | Independent mould design capability | | Commissioning production capacity | Rich stocks | | Materials development | Quality Control by 24 hours |

♦ Sealed storage, keep the products surface clean

♦ Placed on shelves without light, in order to prevent the materials aging♦ Stored products by horizontal.♦ Classify products by different specifications, delivery quickly. |

| OUTSIDE DIAMETER Below diameter is just part of our inventory, welcome to inquire more specifications. |

| φ 1.5 | φ 2.5 | φ 3 | φ 5 | φ 6 | φ 8 | φ 10 | φ 12 | φ 20 | φ 25 | | φ 30 | φ 40 | φ 50 | φ 60 | φ 70 | φ 80 | φ 90 | φ 100 | φ 110 | φ 120 | | φ 130 | φ 140 | φ 150 | φ 155 | φ 160 | φ 164 | φ 172 | φ 180 | φ 190 | φ 200 | | φ 225 | φ 250 | φ 300 | φ 400 | φ 500 | φ 600 | φ 700 | φ 800 | φ 900 | φ 1000 |

|

| |

| We have more than 3000 square meters of warehouses to store tubes which contains more than 80 different sizes. The total inventory over 50 tons.

The tubes are stored by stand-up. The warehouse is insulated and shaded, significantly reduce the risk of tube's distortion and aging. |

|

|

|

translucent acrylic tube square clear acrylic tube white acrylic tube

JINAN ALANDS PLASTIC CO., LTD, founded in 1994, is a high-tech enterprise specializing in researching, producing and selling of new-type plastic materials. We handle all kinds of plastic materials (PMMA, PP, PVC, PS, PC) in TUBES, RODS, SHEETS. The product main supporting for lighting companies and advertising printing companies.♦ ADVERTISING ♦ INDOOR LIGHTING ♦ CONSTRUCTION ♦ BIOLOGICAL PROJECT♦ DECORATIVE ♦ OUTDOOR LIGHTING ♦ TRANSPORTATION LIGHTING (TRAIN, SUBWAY)

Detailed Images

| Material | PMMA |

| Specification | Dia1.5mm-1000mm |

| Length | Unlimited |

| Thickness | 0.3mm-20mm |

| Shape | Round, square, Oval,Irregular |

| Color | Transparent, frosted, milk white, more colors |

| Usage | lighting, building, house decoration, advertising, and the other different functions. |

MATERIAL SELECTION♦ Select international material brands of Germany and Japan.♦ We have professional experience of the same series materials for 8 years. It helps us to ensure material's stability.PRODUCTION PROCESSING♦ Using an extruding machine of better plasticization, can make a fuller integration of plasticized materials.♦ According to ISO Quality Control System to record the technology processing, all of product information can be traced. We strictly enforce the process, to ensure the product's consistency.♦ Technology Department will analyse the feedback datas, constantly improve the technical maturity and quality stability.QUALITY CONTROL♦ The product should pass five full-parametric test and a fully parametric sampling which from production to delivery, thus ensure product quality standards conforms with company's standards.♦ Customer's special requirements will be joined and strictly enforced in the inspection standards, to ensure that customers are satisfied with our products.MATERIAL HEAT TREATMENT♦ Annealing treatment of multiple materials can maximize removed the material's stress. In the latter of processing applications, materials can be more stable and durable.♦ Each product has passed the STRESS TEST to ensure its stress in qualified ranges, reducing the risk of cracking and discard which caused by stress in the processing.ABOUT PACKAGINGGenerally we use PE package or stretch film to wrap each tube, a number of tubes are put in a carton box for shipping. We use high quality paper to produce a variety of cartons, try to reduce the damage in transportation.

Related Products-acrylic rod

Trade ShowsCustomer Visit

Buyer Feedback